Collaborative robots

Cobots, or collaborative robots, have become integral in various industries due to their versatility and ability to work alongside human operators.

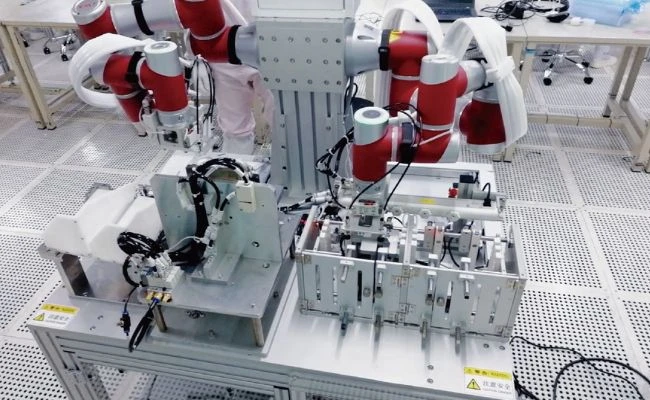

Assembly

- Cobots excel in assembly tasks, whether it’s putting together intricate components in electronics or assembling parts in automotive manufacturing. Their precision and adaptability make them ideal for tasks that require delicate handling and accuracy.

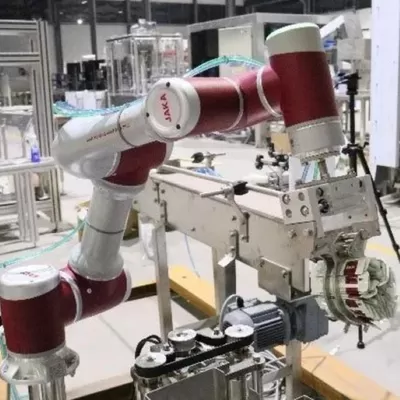

Machine tending

Cobots are adept at tending to various machines, from CNC machines to 3D printers. They can load and unload materials, monitor processes, and perform routine maintenance tasks, reducing downtime and increasing overall efficiency.

Quality inspection

Cobots equipped with vision systems are employed for quality inspections in manufacturing processes. They can quickly and accurately identify defects, ensuring that only products meeting specific criteria move forward in the production line.

Palletizing

Cobots can handle the repetitive and labor-intensive task of palletizing products. They efficiently organize and stack goods on pallets, streamlining warehouse and logistics operations.

Packaging

- Automating packaging tasks with cobots ensures speed and accuracy. They can pick, pack, and palletize products, optimizing the packaging process in industries ranging from food and beverage to logistics.

Polishing

- Precision tasks like polishing can be demanding, and cobots are well-suited for this application. Whether it’s metal polishing in manufacturing or finishing surfaces in industries like electronics, cobots ensure consistent quality.

Pick and place

- Cobots are highly efficient in pick and place applications, swiftly handling items from one location and placing them in another. This is widely used in industries like e-commerce and logistics for order fulfillment.

Gluing

In applications like woodworking or product assembly, cobots can efficiently handle glueing tasks. Their precise movements ensure consistent application, contributing to the quality of the final product.

Painting

- Cobots equipped with painting tools find applications in industries such as automotive and furniture manufacturing. Their precise movements contribute to even coating and improved finishing in painting tasks.

Screw driving

- Cobots with screw-driving capabilities are used for tasks such as fastening components together. Their precision and ability to adapt to different screw sizes make them valuable in assembly lines.

Welding

Cobots in welding applications offer increased efficiency and flexibility. They can handle various welding tasks, including spot welding and arc welding, contributing to the automation of welding processes in industries like automotive and metal fabrication.